- Products

- Aerospace Fittings

- Energy Power

- Petrochemical

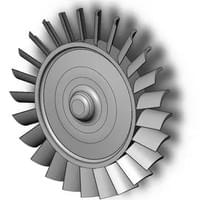

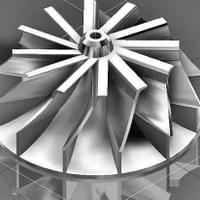

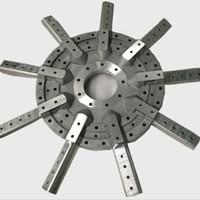

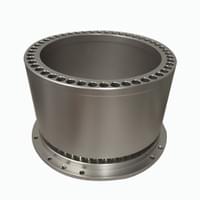

- Gas Turbine

- superalloys fasteners

- Sputtering Targets

- Stainless steel Fabrication

- …

- Products

- Aerospace Fittings

- Energy Power

- Petrochemical

- Gas Turbine

- superalloys fasteners

- Sputtering Targets

- Stainless steel Fabrication

- Products

- Aerospace Fittings

- Energy Power

- Petrochemical

- Gas Turbine

- superalloys fasteners

- Sputtering Targets

- Stainless steel Fabrication

- …

- Products

- Aerospace Fittings

- Energy Power

- Petrochemical

- Gas Turbine

- superalloys fasteners

- Sputtering Targets

- Stainless steel Fabrication

About Us

Your reliable Superalloy Parts manufacturing expert

Artisan Industry is professional super alloy products supplier (Nickel based alloy: Incoloy800series, Inconel600series, Hastelloy C-276, Monel400 series, Cobalt-Based Alloy ), our team with more than 10 professional precision vacuum casting engineers and CNC machining experts, responsible for high temperature alloy products' technical support and customer service.

Our factory specialized in Military equipments R&D and production, considering the confidentiality factor, so we are responsible for their sales agents.

Factory covers an area of 30, 000 square meters and has more than 340 workers.

1, Common Investment Casting Process ( mainly involving instruments, auto parts, ships, pumps and valves, etc.)

2, Vacuum Casting Process ( mainly applicated in aerospace, medical, military equipments etc.)

3, Precision Machining ( material including super alloys, aluminum alloys, titanium alloys, Stainless steel )

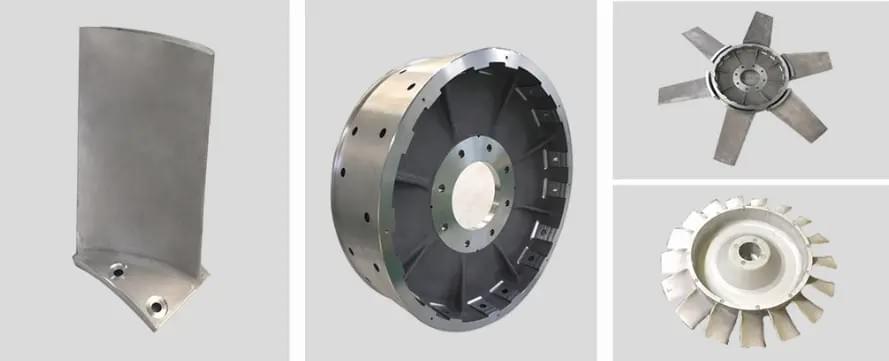

The superalloy project business mainly focuses on high-end manufacturing applications such as Aero-engines, Gas turbines, Aerospace and Energy power, New energy, etc. Focus on precision casting and machining services for Turbine Rotors, Stators, Vane and other engine core components.

Factory has comprehensive capabilities from product process design, vacuum casting, precision machining and ultimate testing. It has more than 30 sets of precision CNC turning and milling processing equipment such as 3 vacuum melting furnaces, German Bruker spectral analyzers, 10 more DMG vertical 3-axis 5-axis, horizontal 4- axis machining centers, wire cutting wire feeders. And core equipment such as Zeiss CONTURA series CMM, German Schenck dynamic balancing machines.

Research and Design Team

- Drawing studies, Material analysis, production technology formulating ,Testing method conform

Precision investment Casting

- Vacuum investment casting for Nickel and Cobalt-based superalloys and titanium alloy,aluminum alloy, low alloy steel, stainless steel, in sizes ranging from a few ounces to 100 pounds

- Permanent mold casting for aluminum parts up to 16 inches in diameter or length and 35 pounds in weight

- Shell mold casting for aluminum parts up to 12 inches in diameter or length and 30 pounds in weight

3/4/5 Axis CNC machining

- CNC precision machining (4-axis and 5-axis equipments) for superalloys,titanium alloy,stainless steel, alloy steel, aluminum to make parts from plates, bar stocks, blank castings and forgings. ensure dimension accuracy.

Heat treatments

- including vacuum gas cooling, vacuum oil cooling, aluminum alloy heat treating, gas nitriding, cold stabilization, stress-relieving and tempering and aging

Surface treatments

- such as anodizing, chemical conversion coating, passivation, plating, stress, and embrittlement relief, etching, painting and dry film application

Quality Control

- CMM dimension inspection, NDT and laboratory testing including X-ray analysis, fluorescent penetrant inspection and magnetic particle inspection

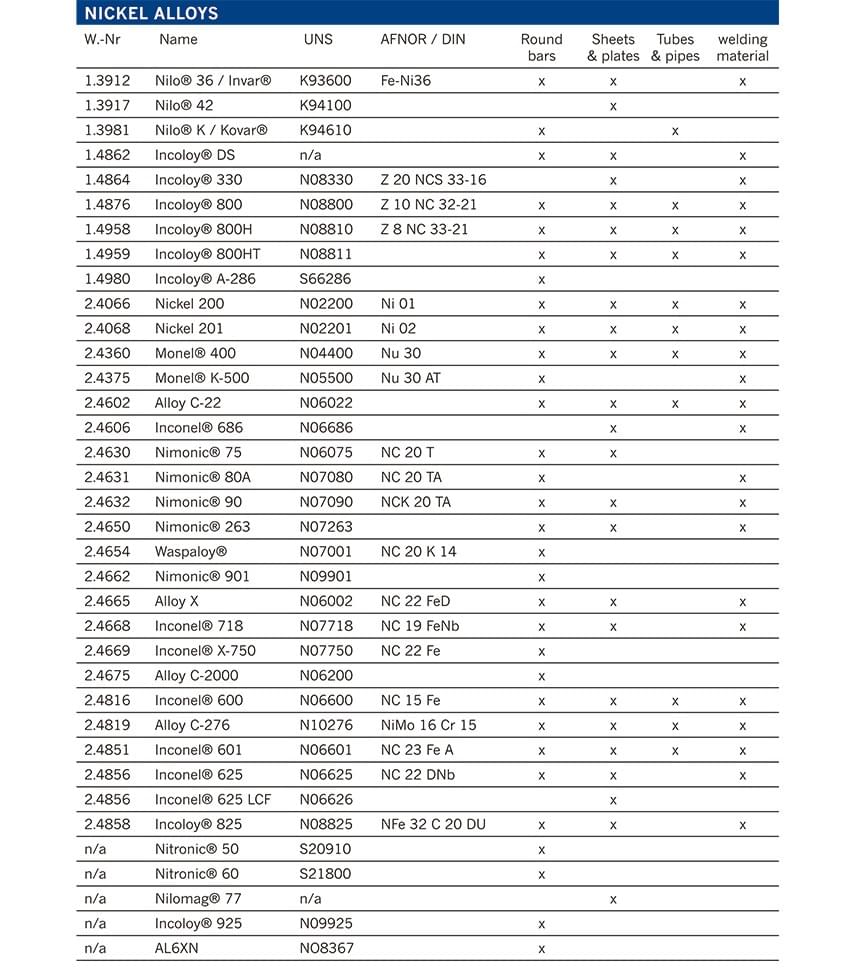

Material Introduction

Aviation Superalloys

mainly Inco718(S400/S1000,B50TF15,C50TF13), Inco625, Alloy HX, Waspaloy

Nickel Alloys

Nimonic® 75 BS 2 HR 5/RRMS 33030/1,

Nimonic® 90 BS 3 HR 2, Nimonic® 901,

Monel® 400, Inconel® 625 LCF,

Incoloy® 825, Alloy C 276, Inconel® 601,

Incoloy® DS, Nickel 201, Nickel 200,

Alloy X AMS 5754/AMS 5536,

Incoloy® A-286 AMS 5732,

Nimonic® 80A BS 3 HR 1,

Inconel® 718 AMS 5662/AMS 5663/AMS 5596,

Nimonic® 75 BS 2 HR 5/RRMS 33030/1,

Inconel® X-750,

Nimonic® 263 AMS 5872,

Inconel® 625 AMS 5666/AMS 5599,

Monel® K-500, Inconel® 686,

Incoloy® 925, Alloy C 22,

Incoloy® 330, Inconel® 600,

Incoloy® 800 H/HT,

Incoloy® A-286,

WASPALOY®, Alloy X,

Inconel® 601, Incoloy® 330,

WASPALOY®, Incoloy® DS,

Incoloy® 800 H/HT, Inconel® 600,

Titanium Alloys

Titanium Gr1, Titanium Gr2, Titanium Gr3, Titanium Gr4, Titanium Gr5, Titanium Gr7, Titanium Gr9, Tit,anium Gr23

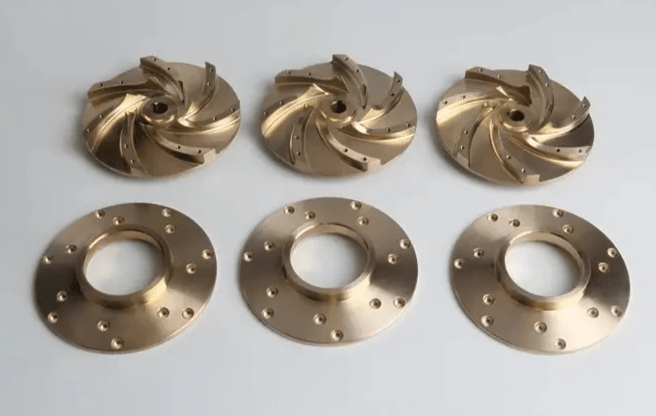

Copper alloy

Brush Alloy 25

Brush Alloy M25

Brush Alloy 174

Brush Alloy 190

Hovadur CB2

Hovadur CCNB

Hovadur CCZ

Hovadur CNB

Hovadur CNCS

CuAl10Ni5Fe4

CuNi10Fe1Mn

CuSn6

Tellurium Copper

Copper comparison sheet

Brush Alloy 3

Heat-resistant alloys

Inconel® 718

Incoloy® 330

Inconel® 600

Inconel® 601

Incoloy® 800 H/HT

Incoloy® A-286

Incoloy® DS

WASPALOY®

Alloy X

Inconel® 601

Incoloy® 330

Alloy X AMS 5754/AMS 5536

WASPALOY®

Incoloy® DS

Incoloy® A-286 AMS 5732

Incoloy® 800 H/HT

Inconel® 600

Special alloys

Nitronic® 60

Nitronic® 50

Nilo® K / Kovar

Nilomag® 77

Nilo® 42 / Invar®

Nilo® 36 / Invar®

Nitronic® 60

Nitronic® 50

Nilo® K / Kovar

Nilomag® 77

Nilomag® 77(2)

Nilo® 42 / Invar®

Nilo® 36 / Invar® ASTM F1684

Creep-resistant alloys

Nimonic® 75 BS 2 HR 5/RRMS 33030/1

Nimonic® 80A BS 3 HR 1

Nimonic® 90 BS 3 HR 2

Inconel® 718 AMS 5662/AMS 5663/AMS 5596

Nimonic® 901

Inconel® X-750

Corrosion-resistant alloys

Nickel 200

Nimonic® 263 AMS 5872

Monel® 400

Inconel® 625 AMS 5666/AMS 5599

Inconel® 625 LCF

Monel® K-500

Inconel® 686

Incoloy® 825

Incoloy® 925

Alloy C 22

Alloy C 276

Alloy C 2000

Nickel 201

Alloy C 2000Questions

What is Nickel-based alloy Castings?

What is Cobalt-based alloy Castings?

How about your factory?

Superalloy parts Application

material:Nickel based alloy, Cobalt alloy, Nimonic, Inconel,Nimonic,Titanium Alloy,Monel,Incoloy series.....

Aerospace

Nimonic® 75 BS 2 HR 5/RRMS 33030/1

Inconel® 718 AMS 5662/AMS 5663/AMS 5596

Inconel® X-750

Alloy X

Nimonic® 80A BS 3 HR 1

Inconel® 625 AMS 5666/AMS 5599

Alloy X AMS 5754/AMS 5536

Nimonic® 90 BS 3 HR 2

Inconel® 625 LCF

Titanium Alloy 6Al-4V

Turbine

Monel® 400

Inconel® 625 AMS 5666/AMS 5599

Alloy C 22

Inconel® 600

Inconel® 625 LCF

Alloy C 276

Incoloy® 825

Inconel® 600

Auto Parts

Inconel® 718 AMS 5662/AMS 5663/AMS 5596

Titanium Gr5

Inconel® 625 AMS 5666/AMS 5599

Titanium Gr1

Medical

Titanium Gr1

Titanium Gr4

Titanium Gr23

Titanium Gr2

Titanium Gr5

Titanium Gr3

Titanium Gr9

Petrochemical equipments

Inconel® 718 AMS 5662/AMS 5663/AMS 5596

Monel® K-500

Alloy C 22

Alloy C 276

Titanium Gr2

Incoloy® 800 H/HT

Monel® 400

Incoloy® 825

Inconel® 601

Titanium Gr5

Inconel® 625 AMS 5666/AMS 5599

Incoloy® 925

Incoloy® 800 H/HT

Inconel® 601

Bellows valves

Nimonic® 75 BS 2 HR 5/RRMS 33030/1

Inconel® 718 AMS 5662/AMS 5663/AMS 5596

Incoloy® A-286

Incoloy® A-286 AMS 5732

Nimonic® 80A BS 3 HR 1

Nimonic® 901

WASPALOY®

Nimonic® 90 BS 3 HR 2

Nimonic® 263 AMS 5872

WASPALOY®Contact with us

Artisan Industry --- > Reliable Super Alloys Parts manufacturing expert

IndustrialPark,JiangAn Town, RUGAO, JIANGSU CHINAMonday-Friday:8:00-18:00+86 150 5061 5346

Artisan industry trading (Nantong) CO.,LTD

Reliable Super Alloys Parts manufacturing expert

Price Inquiry:

sales.lily@

Technical Support:

eng.daisy@

Copyright © 2025